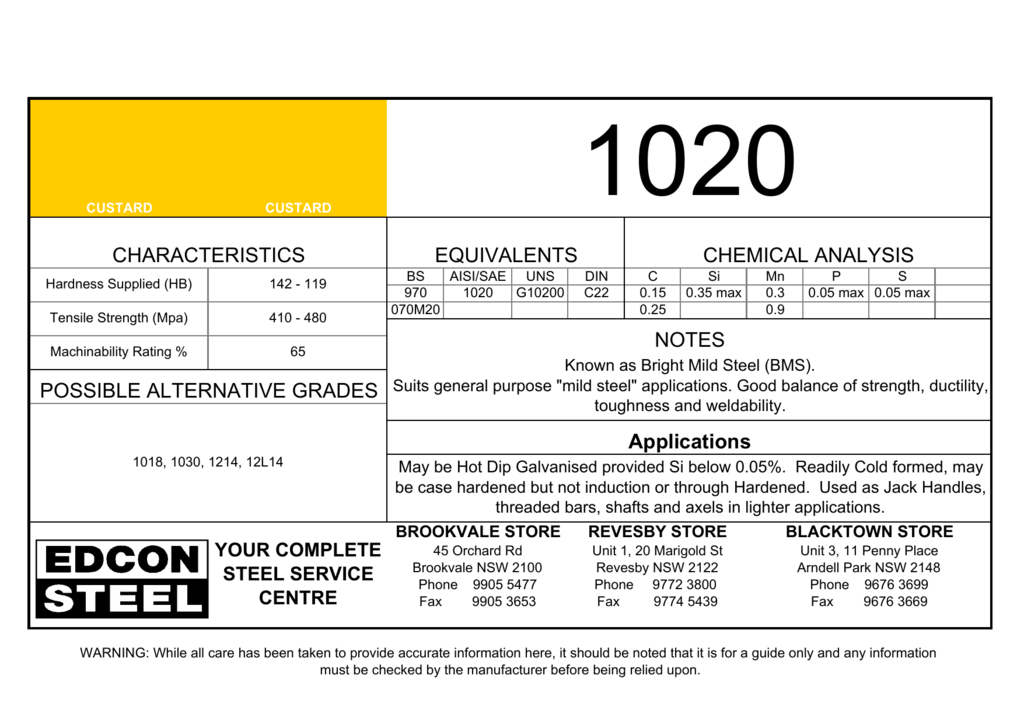

Manufacturer of C1018 STEELCOLD ROLLED FLAT BAR available in a number of sizes to suit your application needs, request a quote or place an order with Metal Supermarkets today CALL US TOLL FREESteel GradesAISI 1018 Chemical information,Mechanical properties Physical properties, Mechanical properties, Heat treatment, and Micro structure AISI 1018 Physical Properties Tensile strength σb/MPa Yield Strength 23 σ 02 ≥/MPa Elongation 65 δ5≥ (%) ψ ψ≥ (%)Tempering AISI 1018 mild/low carbon steel is tempered at 150°C – 0°C to improve case toughness This process has little or no effect on hardness Grinding cracks are reduced when AISI 1018 mild/low carbon steel is tempered Annealing The AISI 1018 mild/low carbon steel is heated at 870°C – 910°C and allowed to cool in a furnace

World Steel Grades Equivalent Us Astm Aisi Sae European En Japan Jis Standard Page 2

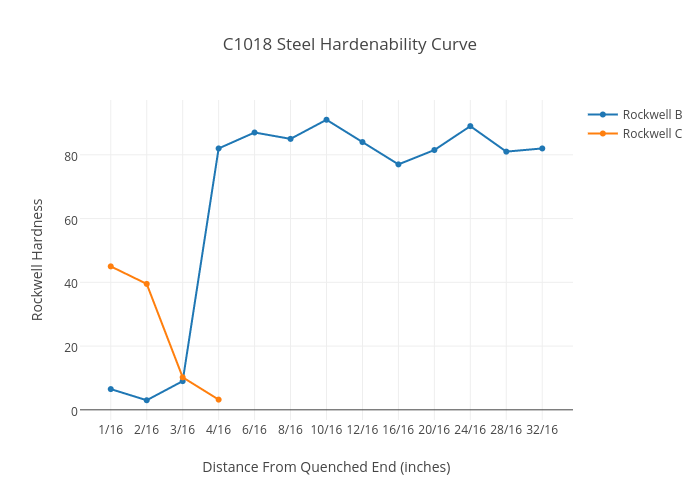

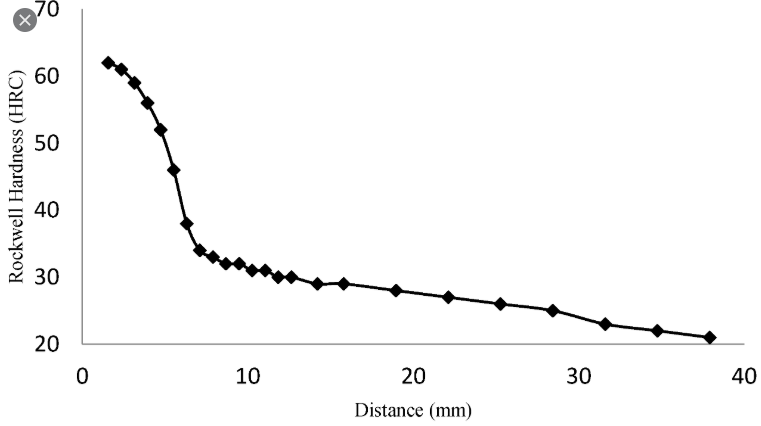

C1018 steel rockwell hardness

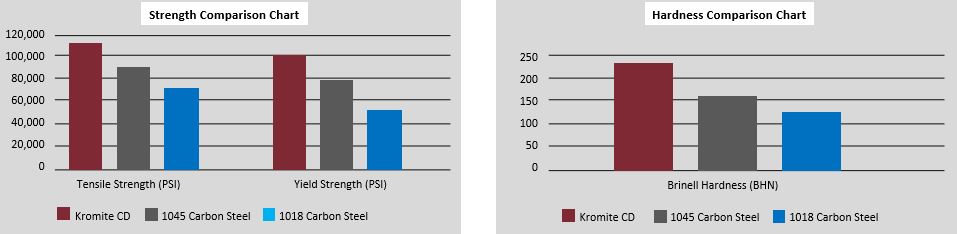

C1018 steel rockwell hardness- Due to its low yield strength of 36,000 PSI, Brinell hardness of 112, and higher ductility, A36 will bend much easier than 1018 (Capital Steel & Wire Inc, 15) Hotrolled 6 is more readily available in larger sections than steel plate 1018, which is more common in the flat bar I have a rockwell tester on hand here I threw the block in (Cold Rolled Steel 1018 that has had a carbon soak) and it showed 1 below 0 on the C scale I was planning on using a stainless steel wrap for getting it up to austenizing temp to keep it from decarbing, using a tiny piece of paper wrapped in to burn and consume the oxygen

Wear Resistance Of 1018 Vs 1024 Kosmeticka Salon Steel Grades

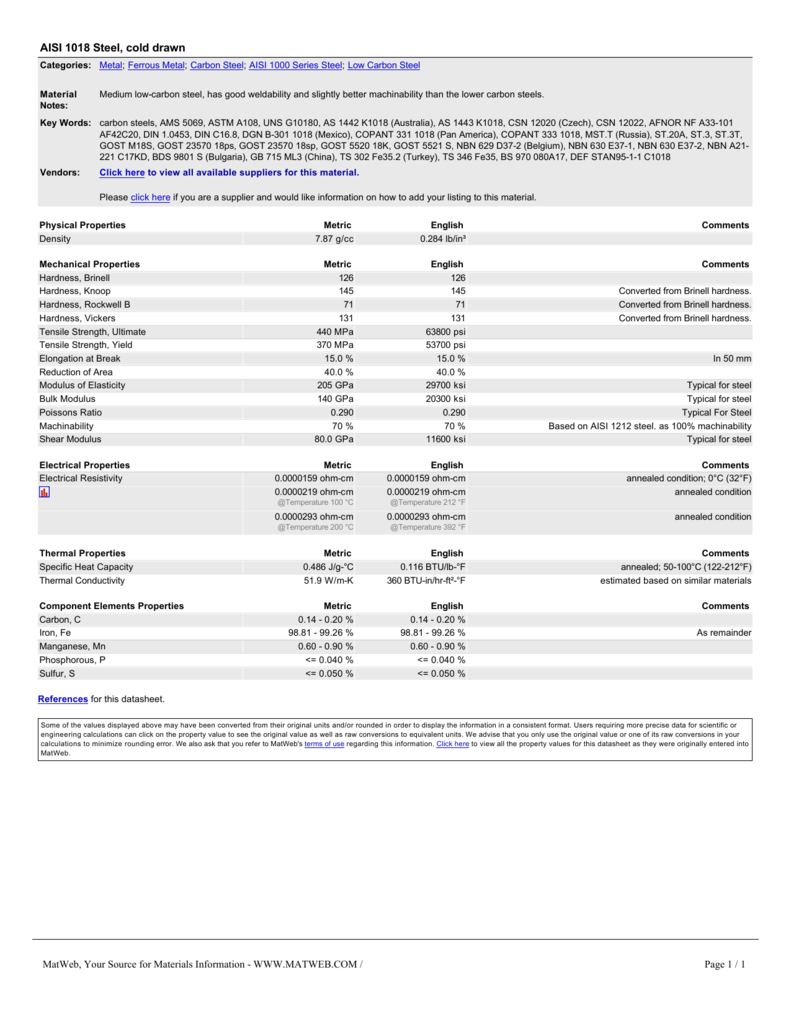

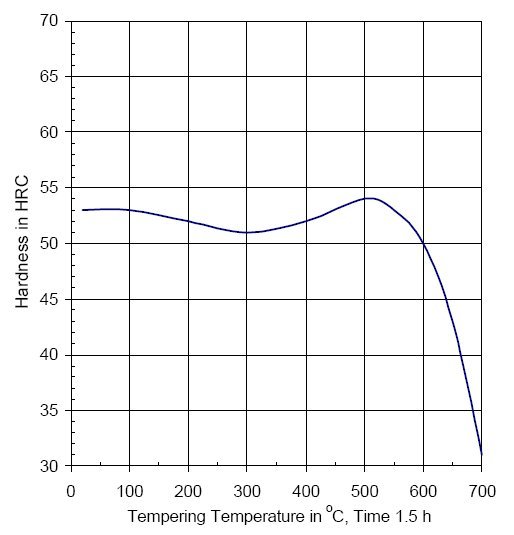

Electrical Resistivity ohmcm @Temperature 0000 °C ohmcm @Temperature 3 °F annealed condition ohmcmAISI 1018 Steel, cold drawn Key Words carbon steels, AMS 5069, ASTM A108, UNS G, AS 1442 K1018 (Australia), AS 1443 K1018, CSN 1 (Czech), CSN 122, AFNORThe C1018 steel sample had hardness close to carburized steel suggesting it had been carburized at 925°C, allowed to box cool, reheated to 775°C, quenched and then tempered at 175°C 2 The hardness of the ductile cast iron suggests an

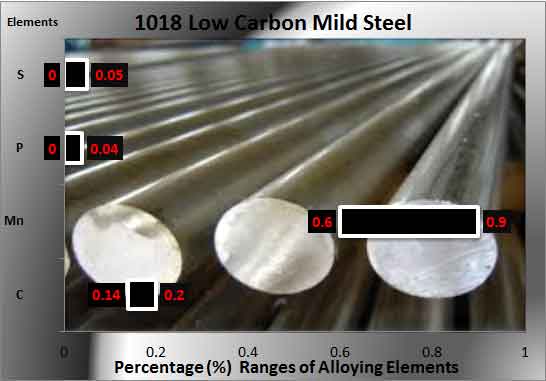

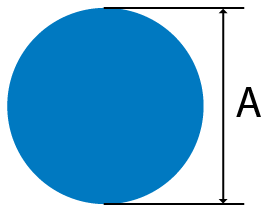

Dimensional Characteristics of 1018 Low Carbon Mild Steel The applicable thickness in millimeters for this 1018 Low Carbon Mild Steel ranges from 0125 to 15 for cold rolled quality whereas the width in millimeters is from 600 to 10, also available in various slit forms of varying width Moreover different sizes & shapes of bars (Rectangular, flat, round, square,AISI C1018 steel (1018 CRS) has good weldability, surface hardening quality, higher mechanical properties and better machinability Cold drawing increases tensile strength, yield strength, torsional strength, surface hardness and wear resistance, but reduces ductility ASTM AISI SAE 1018 hot rolled steel is also known as 1018 HR, and has good Rockwell Hardness of steel 1018 ranges from 71 to 78 converted from Brinell hardness The difference from 71 to 78 is caused by manufacturing metods

Provided with higher mechanical properties, AISI 1018 cold rolled carbon steel also includes improved machining characteristics and Brinell hardness Specific manufacturing controls are used for c1018 steel surface preparation, chemical composition, rolling and heating processes1018 Cold Roll Steel C1018 is a general purpose low carbon steel with good case hardening qualities It has a higher manganese content than certain other low carbon grades, such as 10 With higher manganese, 1018 is better steel for carburized parts, since it produces a harder and more uniform caseC1018 Cold Finished Round, aka CRS Round or Cold Roll Round Bar is a steel product with closer dimensional accuracy, tolerances, and smoother surface finish than hot rolled barC1018 Cold Finish Round is a general purpose low carbon steel with good case hardening qualities and is especially suited for cold forming and bending

Ehu Eus

2

Abstract The purpose of this experiment were to utilize the hardness as an index of mechanical properties to relate the mechanical properties of ferrous and nonferrous metal to their areas of application, and to determine the ef fect of chemical composition on the hardness of these metals What is 1018 steel made of?Characterization of hardened cylindrical C1018 steel rods (014%02% C, 06%09% Mn) using photothermal radiometry Wang C(1), Mandelis A Author information (1)Institute of Modern Optical Technologies, Suzhou University, Suzhou, Jiangsu , People's Republic of China

Sae 1018 Carbon Steel Sae 1018 Forging Sae 1018 Flat Saaj Steel

1018 Cold Rolled Steel Square Bar Coremark Metals

C1018 Steel C1018 is a general purpose low carbon steel with good case hardening qualities It has a higher manganese content than certain other low carbon grades, such as 10 Cold Rolled C1018 is better steel for carburized parts, since it produces a harder and more uniform case Due to size limitations of the cold drawing process, largeChemically, it is very similar to A36 Hot Rolled steel, but the cold rolling process creates a better surface finish and better properties Typically used in pins, rods, shafts, spindles, and sprockets Common Trade Names UNS G, AISI 1018, C1018, Marshallcrat Other Resources Safety Data Sheet Weight Calculator Mill Test Reports1018 Mild Steel 1018, 10 (HR,CF) Low carbon steelHas good hardening properties, fair machinabilityReadily brazed and weldedAlloy 1018 is the most commonly available of the coldrolled steels It is generally available in round rod, square bar, and rectangle bar

Aisi 1018 Carbon Steel Round Bar Hot Rolled Sae 1018 Rod Flat Bar

C1018 Steel Hardenability Curve Scatter Chart Made By Taijuonfire Plotly

AISI 1000 Series Steel;Manufacturer of C1018 STEELCOLD ROLLED SQUARE BAR available in a number of sizes to suit your application needs, request a quote or place an order with Metal Supermarkets today CALL US TOLL FREE ASTM A36 steel for knives ASTM A36 metal food protected It's power, formability, and glorious welding properties make it suitable for a large number of functions, together with welding, fabricating, and bending It also needs to be noted that A36 has a decrease yield energy than C1018 which ends up in elevated bending capabilities over

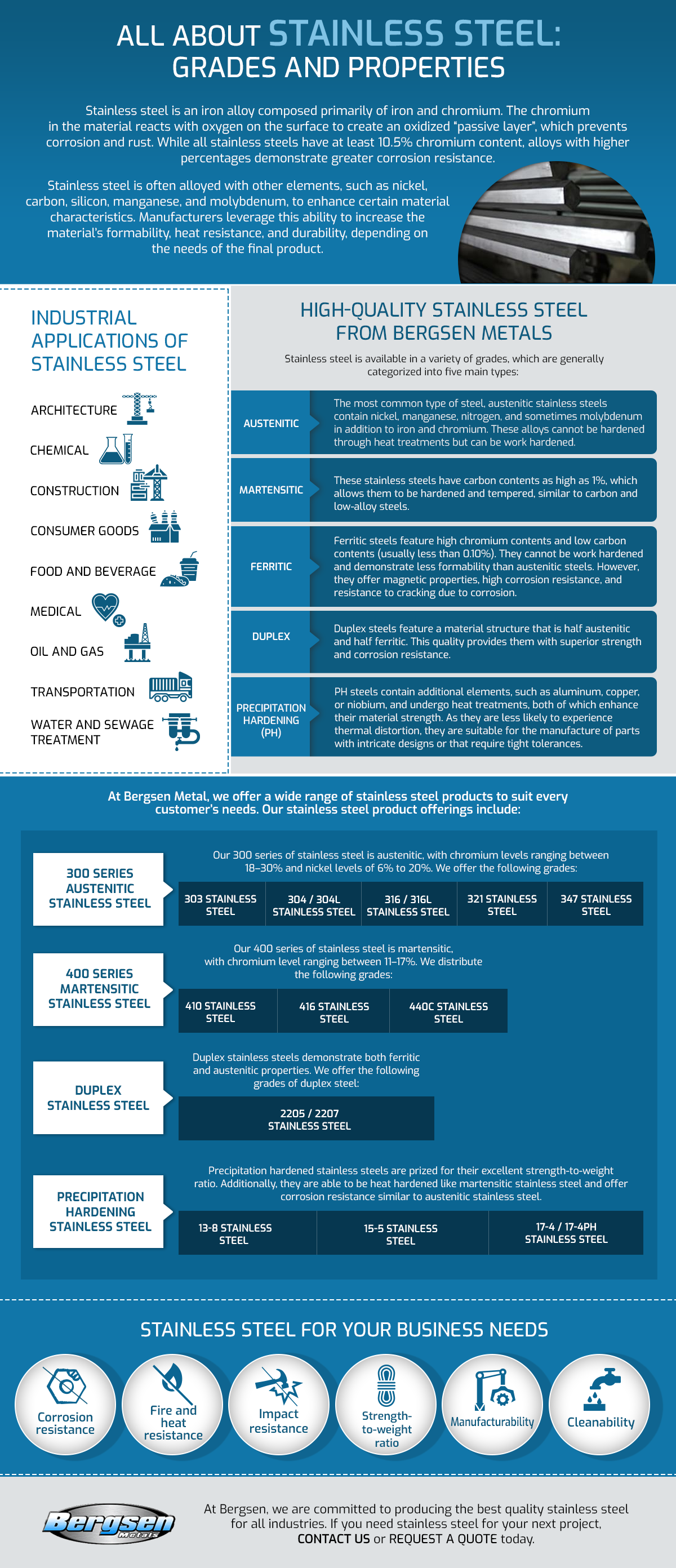

Stainless Steel Grades And Properties Bergsen Metal

Figure5 Flow Curves Of Aisi 1018 Steel In Annealed And Austempered Download Scientific Diagram

Rockwell Hardness 1 Iron (Fe) 91 9926% Carbon 018% Manganese (Mn) 06 09% Phosphorus (P) 004% max Chemistry Sulfur (S) 005% max A36 Mild Steel ASTM A36 steel is the most commonly available of the hotrolled steels It is generally available in round rod, squareC1018 Cold Drawn Steel There are many types of steel, each with differing chemical components and varying methods of manufacturing that suits them for distinct purposes C1018 cold drawn steel is a lowcarbon steel that goes through a specific manufacturing process to make itApproximate Hardness Conversions For Steel 56 60 65 71 76 81 85 90 95 100 105 110 114 117 1 122 125 128 132 135 138 142 145 149 153 157 162 168 171 176 181 1 194 1 8 215 222 Tensile Strength (Approx) ksi 657 698 407 787 9 860 878 907 928 946 964 978 990

Aisi 1018 Steel Cold Drawn

1018 Carbon Steel Coil

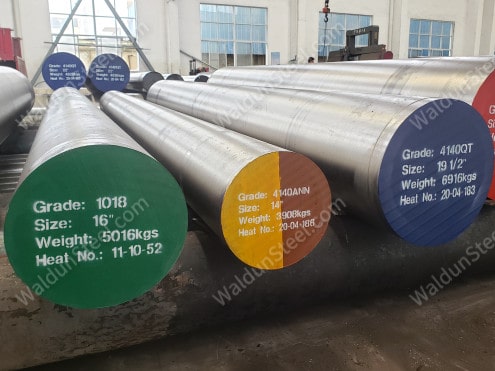

Steel hardness in the United States is commonly measured using the Rockwell C scale (HRC) The higher the number on the HRC scale, the harder the steel Hardness should not be confused with brittleness Steel hardness is about how the material reacts when tested to see how deep a diamond tip indenter penetrates under a 150 kg load Annealed SAEAISI 4140 vs SAEAISI 1018 Steel Both annealed SAEAISI 4140 and SAEAISI 1018 steel are iron alloys They have a very high 98% of their average alloy composition in common There are 31 material properties with values for both materials Properties with values for just one material (1, in this case) are not shown AISI 1018 mild/low carbon steel offers a good balance of toughness, strength and ductility Provided with higher mechanical properties, AISI 1018 hot rolled steel also includes improved machining characteristics and Brinell hardness Specific manufacturing controls are used for surface preparation, chemical composition, rolling and heating

1 2344 Tool Steel Tool Steel Specification And Information

1 2 X 1 X 2 C1018 Low Carbon Steel Ground Flat Stock Fastenal

AISI C1018 steel (1018 CRS) has good weldability, surface hardening quality, higher mechanical properties and better machinability Cold drawing increases tensile strength, yield strength, torsional strength, surface hardness and wear resistance, but reduces ductility ASTM AISI SAE 1018 hot rolled steel is also known as 1018 HR, and has goodSteel Grades1018 Chemical information,Mechanical properties Physical properties, Mechanical properties, Heat treatment, and Micro structure Cu≤02% 1018 Physical Properties Tensile strength σb/MPa Yield Strength 23 σ 02 ≥/MPa Elongation 65 δ5≥ (%) ψ ψ≥ (%) Akv Akv≥/J1018 is a free machining grade and is among the most commonly available grades in the world It is widely available in cold finished rounds, squares, flat bar and hexagons Despite its unimpressive mechanical properties, the alloy is easily formed, machined, welded and fabricated Due to its higher Mn content, it can, in thin sections, be

Technical Datasheets

Astm Sae Aisi 1018 Carbon Steel Chemical Composition Mechanical Properties

Get access to over 8,000 types, shapes and grades of metal We carry hot and cold rolled steel, aluminum, stainless steel and much more 1018 steel and ± 1565 J for FCC 304 steel Furthermore, the average impact energy measured at 196 ºC was 225 ± 358 J for BCC 1018 steel and ±1571 J for FCC 304 stainless steel FCC 304 stainless steel did not have ductile to brittle transition whereas BCC 10181018 Cold Roll Bearing Quality C1018 is a general purpose low carbon steel with good case hardening qualities It has a higher manganese content than certain other low carbon grades, such as 10 With higher manganese, 1018 is better steel for carburized parts, since it produces a harder and more uniform case

The Billavista 60 Bomb Proof Dana 60 Part 1a The Tech Behind The Talk Steel And Material Strength Pirate 4x4

China Aisi 1018 En2c Forged Carbon Steel Round Bar With Ut Sep 1921 84 D D China 1018 Steel 1018 Steel Rod

Both SAEAISI 1018 steel and SAEAISI 4140 steel are iron alloys They have a very high 98% of their average alloy composition in common There are 31 material properties with values for both materials Properties with values for just one material (1, in this case) are not shown For each property being compared, the top bar is SAEAISI 1018 Known for its good mix of strength, ductility and hardness, 1018 steel is a mild, lowcarbon steel This alloy of steel has a small percentage of manganese to help achieve these properties While other steels can exceed its mechanical properties, 1018 steel is more easily manufactured and machined, reducing its cost Cold rolled steel is stronger than hot rolled because it's work hardened If you try to heat treat it, the first thing that will happen is that it will anneal, and you'll lose that extra strength As others have pointed out, 1018 doesn't really have enough carbon to heat treat

Metalsdepot 1018 Cold Finished Steel Square Bar

Aisi 1018 Steel As Cold Rolled Quality In American Standard

C1018 is a general purpose low carbon steel with good case hardening qualities It has a higher manganese content than certain other low carbon grades, such as C10 With higher manganese, C1018 is better steel for carburized parts since it produces a harder and more uniform caseCold Roll Steel Rectangle Bar 1018 Cold Finish Over 6 / 0013" Width governs the tolerances both width and thickness for rectangle bars If the bar is 15" thick x 35" wide, the width tolerance of /0006" will be the tolerance for the thickness asLow Carbon Steel Material Notes Medium lowcarbon steel, has good weldability and slightly better machinability than the lower carbon steels Key Words carbon steels, AMS 5069, ASTM A108, UNS G, AS 1442 K1018 (Australia), AS 1443 K1018, CSN 1 (Czech), CSN 122

1018 Cold Roll Bearing Quality Alcobra Metals

1018 Cold Finished Carbon Steel Bar Alro Steel

1018 Cold Roll Steel C1018 is a general purpose low carbon steel with good case hardening qualities It has a higher manganese content than certain other low carbon grades, such as 10 With higher manganese, 1018 is better steel for carburized parts, since it produces a harder and more uniform case It also has higher mechanical propertiesCase hardness values of Rc 58 may be obtained on carburized C1018 Tempering AISI 1018 mild/low carbon steel is tempered at between 150°C – 0°C for improvement of case toughness This process has little or no effect on hardnessTypical for steel Machinability 70 % 70 % Based on AISI 1212 steel = 100% Shear Modulus 780 GPa ksi Estimated from elastic modulus Electrical Properties Metric English Comments;

1018 Carbon Steel Coil

Inspection Of An End Quenched 0 15 0 2 C 0 6 0 9 Mn Steel Jominy Bar With Photothermal Radiometric Techniques Journal Of Applied Physics Vol 96 No 4

Known for its good mix of strength, ductility and hardness, 1018 steel is a mild, lowcarbon steel This alloy of steel has a small percentage of manganese to help achieve these properties While other steels can exceed its mechanical properties, 1018 steel is more easily manufactured and machined, reducing its cost

Difference Between A36 Vs 1018 Steel Surprising Answer

2

Wear Resistance Of 1018 Vs 1024 Kosmeticka Salon Steel Grades

.jpg)

Aisi 1018 Mild Low Carbon Steel

Cdn Cms F Static Net

Carbon Steel Aisi 1018 Fasteners Manufacturer Exporter Ubique Alloys Pvt Ltd

Steel Grade Identification And Selection Information

China Aisi 1018 Cold Drawn Steel Bar Cold Rolled Steel C1018 China Steel Bar Steel Round Bar

Carbon Steel Wire Cloth Grating Expanded Perforated Sheet Marco Specialty Steel

China Aisi Astm 1018 En2c Non Alloy Engineering Steel China 1018 Steel 1018 Forged Steel

1018 Carbon Steel Coil

Aisi 1018 Carbon Steel Round Bar Hot Rolled Sae 1018 Rod Flat Bar

2

Hot Rolled Vs Cold Rolled Steel Capital Steel Wire

1 2344 Tool Steel Tool Steel Specification And Information

Acero Laminado En Frio Barra Plana 1018 3 4 X 6 X 36 Ebay

Medium Carbon Steel

General

China Aisi 1018 Cold Drawn Steel Bar Cold Rolled Steel C1018 China Steel Bar Steel Round Bar

2

1018 Cold Drawn Steel Bar Supplier Cd 1018 Bar Eaton Steel Bar Company

Customized C1018 1045 Carbon Steel Coil Plate Suppliers Manufacturers Factory Direct Wholesale Aotian

8 Inch Forged Chef Knife 5cr15mov Steel Utility Kitchen Knives Cooking Tool Ebony Wood Handle Cleaver Slicing Meat Chef Knives Kitchen Knives Aliexpress

1

1

Aisi Astm 1018 En2c Non Alloy Engineering Steel

China Sae 1018 En2c Hot Rolled Plate Round Bar Prime Mild Carbon Steel China 1018 Round Bar 1018 Steel Plate

Aisi 1018 Carbon Steel Waldun Steel

China Aisi 1018 Cold Drawn Steel Bar Cold Rolled Steel C1018 China Steel Bar Steel Round Bar

Order 0 25 Mild Steel Square Bar 1018 Cold Finish Online Height 1 4

1060 Steel

Typical Stress Strain Relationship Curves For Cds Aisi 1018 At Download Scientific Diagram

2

Cold Rolled 1018 Steel Round Bar Cold Rolled Steel Bar Cold Rolled Steel Steel

C1018 Cold Drawn Steel Bergsen Metal

Things To Consider While Choosing Best Quality Of Carbon Steel By Astec Steel Medium

Carbon Steel Aisi 1018 Angle Aisi 1018 Carbon Steel C Channel Carbon Steel Aisi 1018 Beam Aisi 1018 Carbon Steel Chain Manufacturers Suppliers

Astm A36 Mildlow Carbon Steel Pdf Steel Strength Of Materials

Customized C1018 1045 Carbon Steel Coil Plate Suppliers Manufacturers Factory Direct Wholesale Aotian

Aisi 1018 Sheet Suppliers In India Aisi 1018 Plate And Sheet Metal

2

Basic Descriptions Of Making Carbon Alloy Stainless And Tool Steel P 4 Carbon Grades Types And Numbering Systems Glossary P Pdf Free Download

Aisi 1018 Cold Drawn Steel Manufacture And Aisi 1018 Cold Drawn Steel Supplier In China

World Steel Grades Equivalent Us Astm Aisi Sae European En Japan Jis Standard Page 2

1

Inspection Of An End Quenched 0 15 0 2 C 0 6 0 9 Mn Steel Jominy Bar With Photothermal Radiometric Techniques Journal Of Applied Physics Vol 96 No 4

Precision Ground Flat Stock C1018 Steel Low Carbon

Low Carbon Flat Ground Stock Alro Steel

C1018 Steel

Aisi 1018 1 0401 C15 080a15 Waldun Steel

Amazon Com 1018 Cold Roll Carbon Steel Rectangular Bar Unpolished Mill Finish Cold Finish Astm 108 0 125 Thickness 0 25 Width 84 Length Onlinemetals Industrial Scientific

Cold Rolled 1018 Steel Square Bar Cold Rolled Steel Bar Cold Rolled Steel Steel

Aisi 1018 Carbon Steel Round Bars For Industrial Single Piece Length 3 6 Meter Rs 65 Kg Id

Doc Astm A36 Mild Asif Ali Academia Edu

Aisi 1018 Carbon Steel 1018 Steel Properties All Metals Forge Group

2

Aisi 1018 Cold Drawn Steel Manufacture And Aisi 1018 Cold Drawn Steel Supplier In China

1018 Steel Properties

Materials Steel Carbon Alloy Grades G L Huyett

Aisi 1018 Carbon Steel Uns G Pdf Txt

Carbon Steel Aisi 1018 Bright Bars Aisi 1018 Cs Round Bar Carbon Steel Aisi 1018 Flat Bars Manufacturer Supplier Stockists

Comparison Of Reduction Factor Data Of The Elastic Modulus Of Cds Aisi Download Scientific Diagram

Amazon Com 1018 Cold Roll Carbon Steel Rectangular Bar Unpolished Mill Finish Astm 108 1 25 Thickness 1 5 Width 72 Length Onlinemetals Industrial Scientific

Cnc Steel Material Cnc Machining Steel Fictiv

1 5 Diameter X 24 Long Today S Only Steel C1018 Rod Round Bar

Aisi 1018 Cold Drawn Steel Manufacture And Aisi 1018 Cold Drawn Steel Supplier In China

Ehu Eus

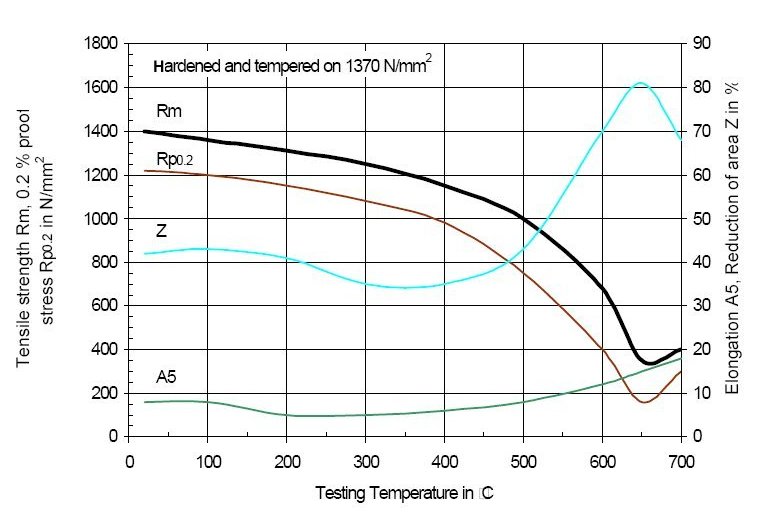

Pdf Experimental Investigation Of Mechanical Properties Of Cold Drawn Aisi 1018 Steel At High Temperature Steady State Conditions

Aisi 1018 Carbon Steel Round Bar Hot Rolled Sae 1018 Rod Flat Bar

C1018 Case Hardening Steel Construction Rs 60 Kg Vinay Steel Corporation Id

Pdf Microstructure And Mechanical Characterization Of Austempered Aisi 1018 Steel

Aisi 1045 Carbon Steel

Mild Steel Round Bar Cold Rolled 1018 Metal Supermarkets

Carbon Steel Aisi 1018 Fasteners Manufacturer Exporter Ubique Alloys Pvt Ltd

Aisi 1018 Sheet

Aisi 1018 Low Carbon Steel 1018 Polished Cold Drawn Bar Alloy Steel Malaysia Selangor Kuala

Aisi 1045 Carbon Steel

4140 Steel Properties Associated Steel Corporation

080a15 1018 Bright Bar En3b Engineering Steel Impact Ireland Metals

Experimental Investigation Of Mechanical Properties Of Cold Drawn Aisi 1018 Steel At High Temperature Steady State Conditions Sciencedirect

2

Heat Treating 1018 Steel Steel Choices

0 件のコメント:

コメントを投稿